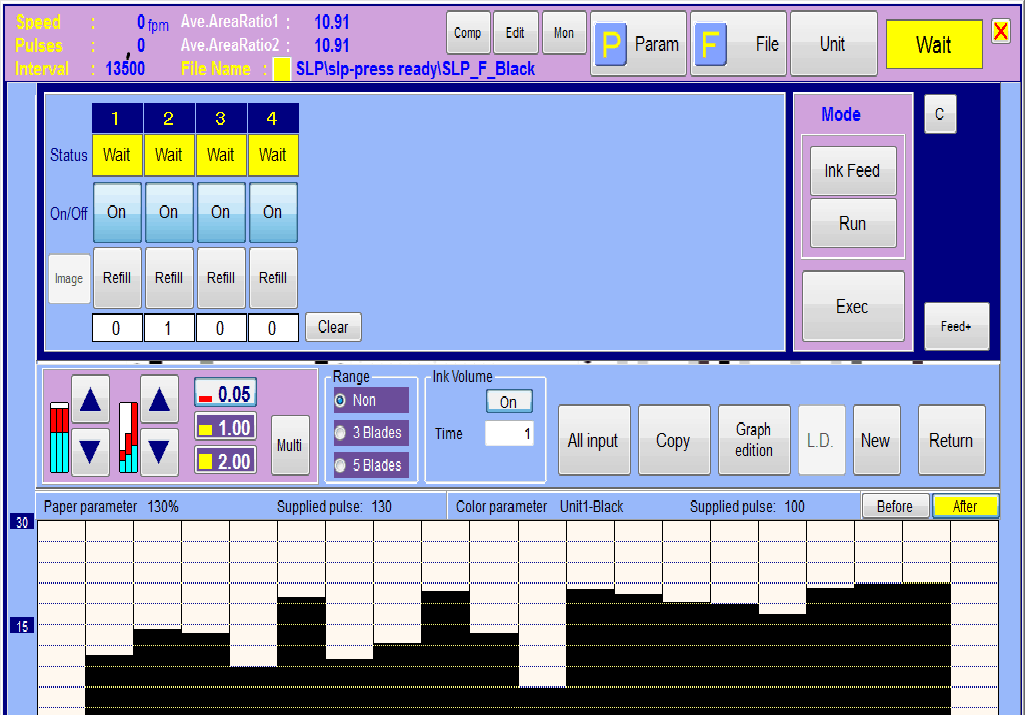

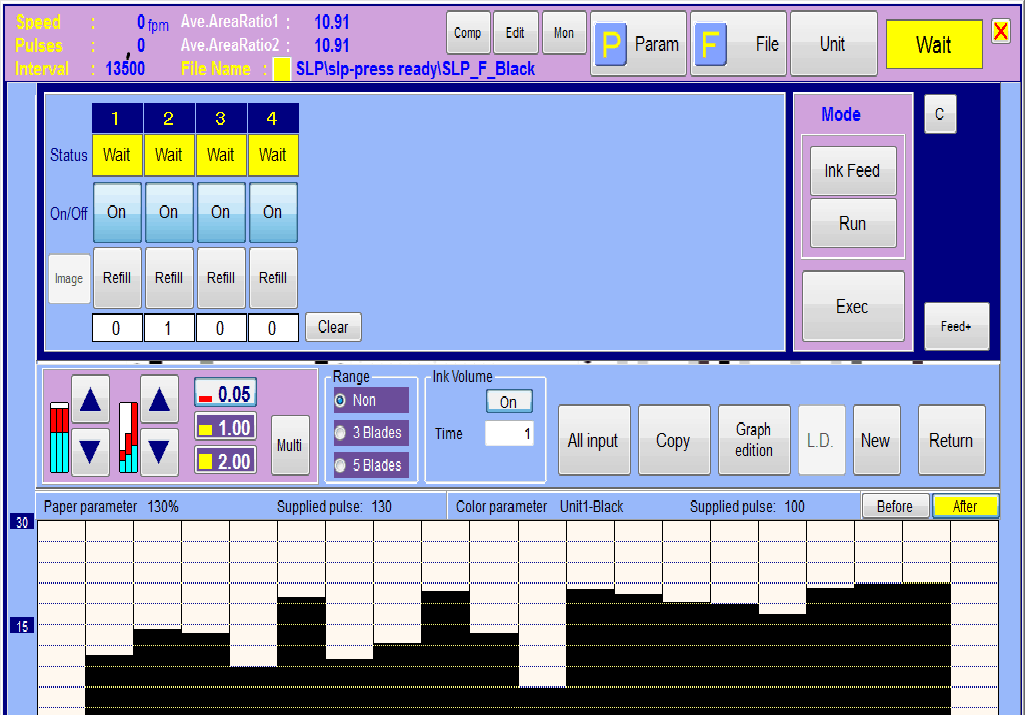

I.Mer Ink Preset Control (IPC) System

Divided Ductor Roller

Why It Matters

The main benefit of I.Mer’s divided ductor technology over conventional “ink key” based systems is the transfer of exact amounts of ink to any zone without compromising other areas of the plate – seamlessly print solids and spot-color side by side.

Why It Matters

The main benefit of I.Mer’s divided ductor technology over conventional “ink key” based systems is the transfer of exact amounts of ink to any zone without compromising other areas of the plate – seamlessly print solids and spot-color side by side.

Since ink levels are pre-determined by I.Mer’s Area Reader (AR) system, classic “ink key” setup headaches are eliminated. Reduces required skillset, reduces time-to-production, reduces waste.

How It Works

I.Mer precisely controls ink distribution across plate zones via two key innovations…

Uniform Ink Film Thickness

A fixed blade evenly and consistently distributes ink across the entire fountain roller. Since ink sweep is based directly on press speed, hydraulic lift and film thickness changes become predictable and repeatable.

Divided Ductor Ink Distribution

Through its pre-scanned “map” of plate zones (created by the Area Reading system), I.Mer knows where the ink needs to go and in exactly what quantities.

Getting it there is achieved with I.Mer’s innovative “divided ductor”, a composite roller made up of individual narrow rollers working together, one for each plate zone.

Each of these narrow rollers can make precisely-controlled contact with the fountain roller based on its zone’s known ink requirements. The longer the contact, the more ink is transferred to the distribution roller – this happens simultaneously across the entire composite ductor roller.

Since the fountain roller ink film thickness is carefully controlled, an exact quantity of ink is delivered to every zone for every impression.